Featuring hydraulic bearings; a cost-efficient compromise between a standard sleeve bearing and a true FDB

bearing

Equipped with a counter-balancing magnet in the hub that reduces the axial tension on the bearing, further protecting

the longevity of the bearing

Optimized fan geometry for a good balance between static pressure and maximum airflow, resulting in good performance

in all usage scenarios

Aerodynamically shaped thin stator struts (including wire strut), mimicking the design commonly found on airplane

wings, delivering correct angles allowing for air to easily pass through reducing noise and unwanted turbulence.

Stator struts are angled perpendicular to the blades, helping to reduce noise commonly emitted when the blades

pass the struts. In effect, minimal noise that may be emitted will be constant and therefore almost inaudible to the

ear.

Strategically placed notches near the fan hub on the trailing edge of the blades, further reducing and diffusing

humming noise produced when the blades pass the stator struts

Includes a “trip wire” on the rear side of the blades, near the leading edge. The trip wire technology, also commonly

found in airplane wing designs, introduces a micro-turbulent layer that helps to combat the elements that negatively

affect performance. The presence of the trip wire overall provides a more efficient and quiet fan environment.

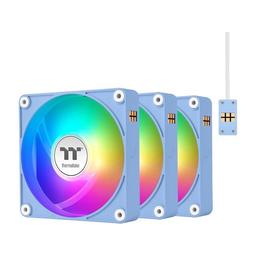

The customized design of the Dynamic Series fans contributes to a beautiful, cool build

Available in 120mm and 140mm fan sizes